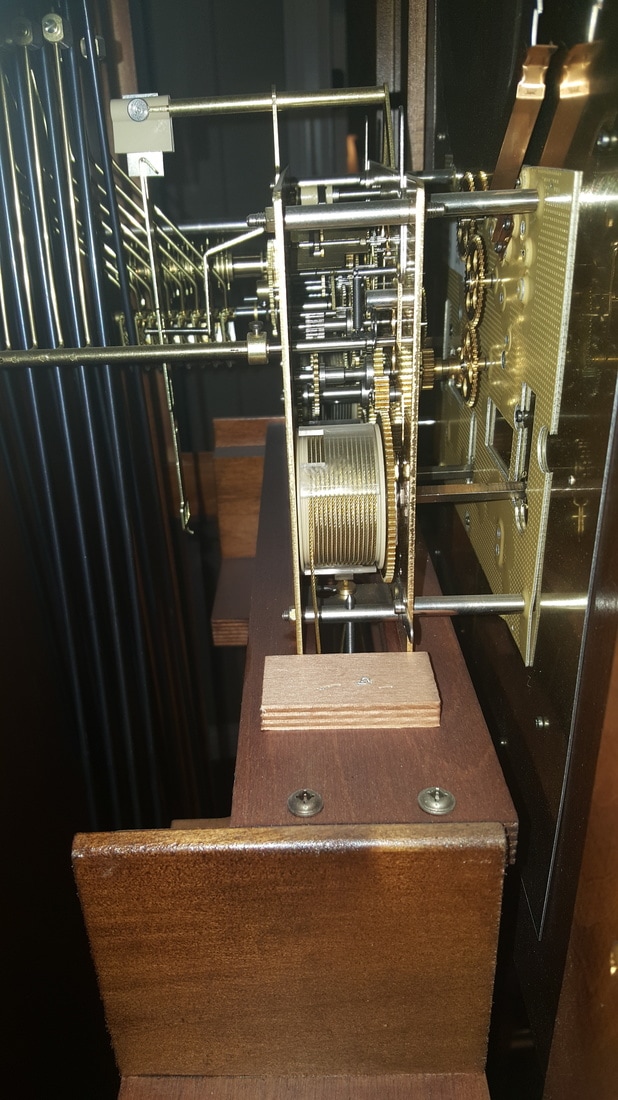

Went out to day to for a repair to a Ridgeway Grandfather clock. The customer was needing the grandfather clock serviced and also "one of the weights had fallen off". In this case the left weight had come apart and fell in pieces down to the bottom of the clock. Fortunately for the customer, the weight was in the lowest position so it did not have far to fall, limiting the damage to the weight shells or caps, or to the bottom of the Grandfather clock. Part of servicing a grandfather clock includes tightening the hooks and the bottom nut to each weight of the Grandfather clock. When we service a Grandfather clock, we notice that allot of our customers Grandfather clock weight hooks are so loose, we are surprised that they are still hanging on. I wanted to show what we did to service this Ridgeway Grandfather clock as well as how we repaired the weight that had come apart. I always repeat myself on allot of these blogs because when we service a Grandfather clock, we always will remove the movement to clean and service the grandfather clock's movement. Sometimes, removing a movement from a grandfather clock case is the biggest challenge of the job. We always start by setting the clock 's hands to 12 o"o'clock. There is a reason behind this step and I will link it to our blog on why we do this. After setting the hands to 12, we will remove the hands as well as the second hand.  Now that the hands are removed we can start to remove the movement form the Grandfather clock. Not all movement come out the same. Some are held in by bolts and some by screws and others by other means, This clocks movement will come out by removing 4 screws on the seat board. Once the 4 screws are removed, we were able to slide the seat board back slightly so that we can remove the front trim piece. On this model, there was a piece of wood up high on the backside of the topside of the face. This piece of wood is to support the top side of the movement and to keep the topside of the movement tight against the front trim piece. We simply just mover the support to the side. After this step, we removed the 4 screws from the seat board then we were able to slide the movement back away from the front trim piece.

Repairing the weight After digging around in the bottom of the Grandfather clock case, we were able to retrieve all the parts that make up a Grandfather clocks weight. Keep in mind there are several sizes of Grandfather clocks weights and each manufacturer will make theirs slightly different. This weight had a few spacer pieces made of cardboard. This cardboard is only for filling dead space. Some manufacturers leave these spacers out and that's fine, they serve no other purpose. There will be an additional blog on how to re assemble the weight. Once we reassembled the weight, we were able to clean and re-oil the Grandfather clock. The Grandfather clock's movement was re-installed and adjusted. We re-leveled the grandfather clocks case and polished the case as well. After testing the Grandfather clock electronically, we ran the clock for 1/2 hour. The Grandfather clock checked out correctly and was running fine.

19 Comments

|

About Us:

Clock Repair Service has been in business for over 10 years now. We service more Grandfather clocks than any other clock company in the state of Georgia. We have 2 Grandfather Clock Technicians that are on the road Monday - Friday repairing 2-3 Grandfather clocks per day, EACH.. That's allot of clocks in the past 10+ years. Our service area at this point is from Chattanooga, Tennessee down to Macon Georgia. The bulk of our Grandfather Clock repairs are however, in the Metro Atalanta area. We service Grandfather clocks ranging from 200+ years old to current models. We do service all brands of Grandfather Clocks and we are an Authorized Sales and Service center for both Howard Miller and Ridgeway clocks. Archives

April 2023

Categories

Let us know if you have any questions 678-462-7856

|

.

RSS Feed

RSS Feed